Ekomat II

Ekomat II Power Unit is designed for the combustion of crumbled biomass waste (sawdust, dusts, wood chips, pellet) of the moisture content of 30% and maximum size of 25 mm.

Ekomat II series boilers are low-temperature, water-operated steel boilers with four draught flue gas circuit. Ceramic combustion chamber, retort furnaces made from cast iron and chromium alloys and multi-point primary and secondary aeration system are incorporated into the boiler’s construction. The flame tube heat exchanger has two flue gas circuits. Fuel is transported to the boiler by a screw conveyor. The biomass is fed to the retort in the combustion chamber, where it is piled up.

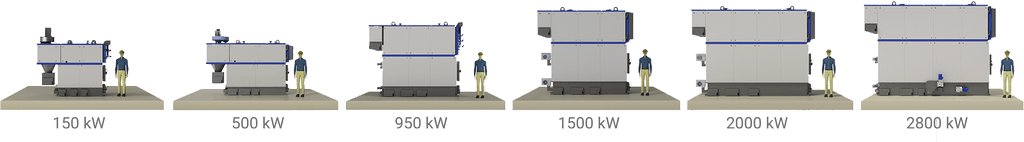

Ekomat II Power Unit is offered in a series of types with capacity range from 520 kW to 2800 kW.

Boilers of Ekomat II series are fully automated. Advanced controllers control all the unit’s operating parameters. In addition, we provide remote access to the control panel, via a mobile app, enabling, among others, online diagnostics.

We offer:

- Design of the installation tailored to the customer’s needs and capabilities

- Mechanical assembly of the installation – connection of all its components

- Electrical installation – delivery and connection of control cabinets including the wiring of the boiler and of all boiler components

- Commissioning works of the unit, setting he boiler’s operating parameters as well as training in device operation and maintenance

Construction of the boiler

|

TECHNICAL DATA |

|||||||

|---|---|---|---|---|---|---|---|

| EKOMAT II | 150 kW | 350 kW | 500 kW | 950 kW | 1500 kW | 2000 kW | 2800 kW |

| Connection DN/PN [mm/bar] | 80/0,6 | 80/0,6 | 80/0,6 | 100/0,6 | 125/0,6 | 150/0,6 | 150/0,6 |

| Flow of exhaust gas [m3/h] | 500 | 1150 | 1600 | 3050 | 4800 | 6400 | 8950 |

| Hydraulic resistance [kPa] | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Water capacity [m3] | 0,5 | 1,0 | 1,4 | 3,0 | 3,4 | 4,7 | 6,9 |

| Diameter of chimney [mm] | 250 | 250 | 300 | 400 | 500 | 500 | 600 |

| Weight [kg] | 3200 | 4500 | 6500 | 13000 | 15000 | 17000 | 19000 |

| Leistung [%] | 80-90 | 80-90 | 80-90 | 80-90 | 80-90 | 80-90 | 80-90 |

| DIMENSIONS | ||||||

|---|---|---|---|---|---|---|

| EKOMAT II | A | B | C | D | E | F |

| 150 kW | 1480 | 900 | 2840 | 2300 | 2685 | 1880 |

| 350 kW | 1630 | 1050 | 2940 | 2400 | 3205 | 2400 |

| 500 kW | 1830 | 1250 | 2920 | 2400 | 3435 | 2600 |

| 950 kW | 1995 | 1400 | 3190 | 3770 | 3200 | - |

| 1500 kW | 2260 | 1650 | 3650 | 3770 | 3200 | - |

| 2000 kW | 2260 | 1650 | 3650 | 4770 | 4200 | - |

| 2800 kW | 2500 | 1800 | 3950 | 5270 | 4700 | - |

Fuel feeding options

Ekomat II with biomass storage and rolled tank. The rake, with a maximum length of 12 m, is driven by hydraulic cylinders. It is designed to transport fuel from the whole storage space to a screw conveyor. Then, fuel is transported to a rolled tank, wherefrom it is fed to a retort located in a combustion chamber.

Ekomat II with rolled 1.8 m3 or 4.2 m3 tank. The tank is equipped with planetary gear driving profiled raking arms. Using a screw conveyor, fuel is fed to the retort located in the combustion chamber.

Ekomat II with 5.5 m3 or 20 m3 container. Containers are equipped with hydraulically driven rakes. They transport fuel from the whole space of a tank to a screw conveyor. Using the conveyor, fuel is fed to the retort located in the combustion chamber.

Production line